- Gloveboxes

Gloveboxes

- Vigor gloveboxes

Vigor gloveboxes

- Cleanroom gloveboxes

- Standard gloveboxes

- Pumps

Pumps

- Diffusion pumps

Diffusion pumps

- Diffstak series

- nHT series

- Semiconductor pumps

Semiconductor pumps

- iXH series

- iXL series

- iXM series

- Multiroots vacuum pumps

Multiroots vacuum pumps

- nXR series

- Industrial pumps

Industrial pumps

- Atex series

- Dry pumps

- GXS series

- Industrial series

- UHV pumps

UHV pumps

- Digital controller

- HyTan

- IGP

- NEG

- TSP

- Cryo pumps

Cryo pumps

- Compressors

- Cryotorr

- OnBoard

- CTI Cryopump Water Pumps

- Diaphragm pumps

Diaphragm pumps

- Atex series

- D-lab series

- LVS series

- MPC series

- RV vacuum pumps

RV vacuum pumps

- RV series

- EM Vacuum pumps

EM Vacuum pumps

- E2M series

- nXDS scroll pumps

nXDS scroll pumps

- nXDS series

- XDS series

- Turbomolecular pump

Turbomolecular pump

- nEXT series

- STPiS series

- STPiX series

- Accessories

Accessories

- Vacuum oil

Vacuum oil

- Ultragrade Performance Vacuum Oil

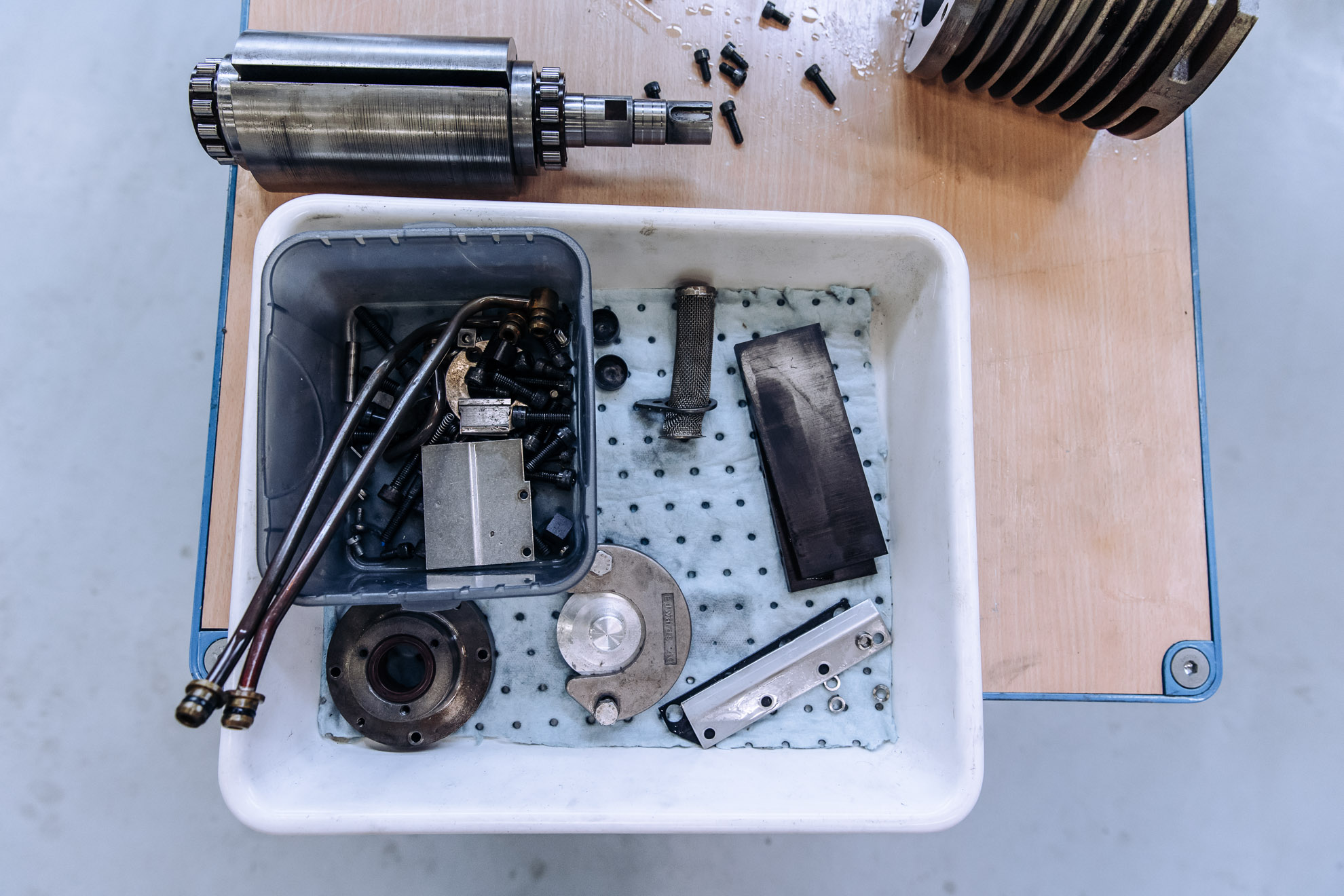

- Spares

- Instrumentation

- Maintenance

- Documentation

07 August 2025

Choosing vacuum oil, everything you need to know for optimal performance

Vacuum pumps are often selected based on capacity, technology, and specifications. But there’s one component that’s just as important—yet often overlooked: the oil. The right vacuum oil not only influences how well your pump performs but also affects its lifespan and energy consumption. In this article, you’ll discover what to look for when selecting vacuum oil, the benefits of using the right type, and how to avoid common mistakes.

why vacuum oil is essential

Vacuümolie doet meer dan alleen smeren. Ze helpt ook bij het afdichten van de kamer, het afvoeren van warmte en het transporteren van gassen. Daarmee draagt de olie direct bij aan het creëren van een stabiel vacuüm. Een verkeerde olie, of te oude olie, kan leiden tot prestatieverlies, vervuiling van je systeem of zelfs schade aan de pomp.

Which oil suits your application?

There are various types of vacuum oil, each with specific properties. The best choice depends on your pump and process conditions:

| Type of oil | Properties | Application |

|---|---|---|

| Mineral oil | Basic and affordable | Standard industrial processes |

| Synthetic oil | Thermally stable, longer lifespan | Continuous use, heavy-duty processes |

| Silicone oil | Extremely low vapor pressure | (Ultra) high vacuum applications |

| PFPE oil | Chemically inert, resists aggressive gases | Cleanrooms, chemical, R&D |

Never mix different oil types and always follow the manufacturer’s recommendations.

How the right oil makes your pump more efficient

High-quality oil reduces internal friction and ensures the pump maintains the correct speed. This brings several clear advantages:

- Shorter evacuation times

- Lower energy consumption

- Improved performance at low pressures

- Reduced thermal load

A small investment in the right oil can lead to significant savings in energy, maintenance, and downtime.

When should you replace the oil?

Many users wait too long to change the oil understandable, since as long as the pump runs, everything seems fine. However, oil quality degrades over time, especially due to heat, oxygen, and process gases. Discoloration, strong odors, or declining performance are signs that it’s time for a change.

Don’t wait for problems—plan regular maintenance. Periodic oil analysis is especially helpful for critical processes to determine the ideal replacement interval.

Common mistakes when using vacuum oil

Mistake 1: using “universal” oil without checking compatibility

While convenient, universal oils often don’t meet the specific needs of your pump or process gas. This can reduce performance and cause wear. Always match the oil to your pump technology and application.

Mistake 2: delayed replacement

Old oil loses its lubricating and sealing abilities, increasing stress on the pump. This can lead to damage, performance loss, or even failure. Regular checks and timely oil changes are crucial.

Mistake 3: mixing oil types

Mixing different oils can cause chemical reactions like sludge formation or thickening. This impairs pump performance and may lead to internal damage. Always use one oil type per pump.

Mistake 4: ignoring chemical load

Process gases such as solvents or acids can degrade standard oils. If the oil isn’t resistant to these chemicals, it becomes contaminated or breaks down quickly. In such cases, use a chemically resistant oil like PFPE.

These mistakes are easy to prevent, but ignoring them can result in costly damage or downtime.

Where to find the right oil

At Acclon, we collaborate with leading chemists to develop advanced vacuum oils and lubricants that boost both performance and efficiency. Our oils are specially formulated for various vacuum pump technologies and retain their quality, even under high temperatures.

Whether you’re looking for oil for a standard application or a demanding process, we offer a comprehensive portfolio tailored to your specific needs.

Explore our vacuum oil products